ZHW series scraper self-cleaning filter

Remove particles on outer surface of filter components by a wiper driven by electric motors continuously with time and pressure difference under control of PLC. It can remove high-concentration impurities in the dirt cavity. The remained residue can be recycled or discharged.

roduct introduction

ZHW series scraper self-cleaning strainer (ZHW filter) is an efficient self-cleaning filter developed by nine companies, which reaches the world leading level. The particle impurities on the surface of the filter are removed by the motor driven scraper, which is used to remove all kinds of high viscosity liquids and continuously clean online, without the need of manual cleaning of the filter element, and no filter consumables are produced. Control the time/pressure control by PLC, automatically eliminate the high concentration of impurities in the contaminated cavity, and eliminate the recovery and discharge of residual liquid.

ZHW filter is suitable for solvent, acid, alkali, polymer, coating of high viscosity material self-cleaning filter, higher efficiency and little pressure loss of the filter, flow stability, save energy consumption of pipeline, is advantageous to the process continuous and stable. Apply to oil, paper, petrochemical, fine chemicals, paint, ink, food and beverage, bio-pharmaceutical industry.

ZHW filter is suitable for solvent, acid, alkali, polymer, coating of high viscosity material self-cleaning filter, higher efficiency and little pressure loss of the filter, flow stability, save energy consumption of pipeline, is advantageous to the process continuous and stable. Apply to oil, paper, petrochemical, fine chemicals, paint, ink, food and beverage, bio-pharmaceutical industry.

Working principle

The liquid passes through the filter inlet, and the liquid flows through the filter screen from the outside of the filter element to the outer surface of the filter. When the external surface of the filter element to collect a certain amount of impurities, motor drive do horizontal rotating cleaning filter element, in addition to the screen surface impurities, impurity gathered in set with the descending liquid dirt cavity, when accumulated to a certain amount of impurities, dirt cavity, automatic drain valve open set will contain high concentration of impurity liquid discharge, discharge residual liquid can be recycled or emissions.

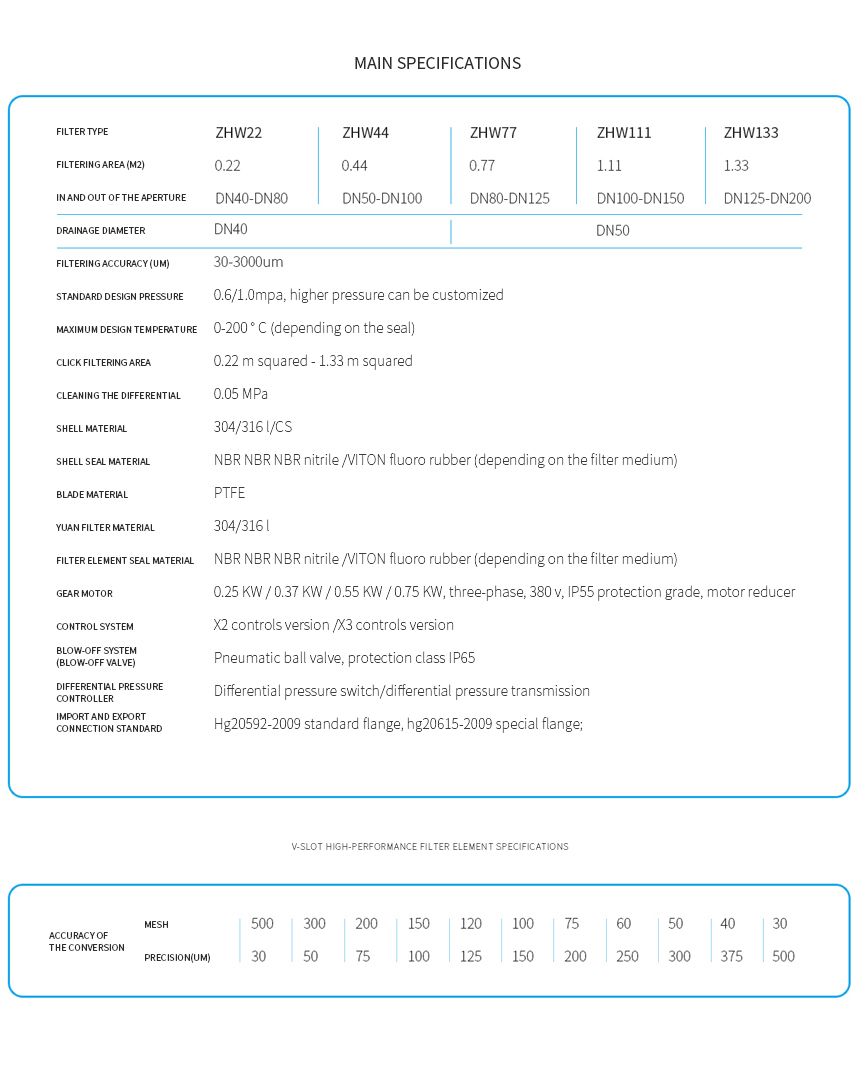

Technical specifications

Technical features and advantages

- The filter pressure loss is minimal, the flow rate is stable, and the energy consumption is saved, which is beneficial to the continuous stability of the process.

- It is fully enclosed filter to prevent leakage of dangerous material, which is beneficial to safe production.

- It adopts unique v-slot filter element, with unique filtering surface structure, excellent scraping effect, uniform and uniform filter opening clearance, which is solid and durable.

- It USES a unique PTFE scraper to remove impurities, and it is good at filtering viscous liquid.

- The concentration of impurities is high and can be recycled to reduce the loss of high value materials.

- Various control systems can be selected, powerful and efficient operation, which can meet the requirements of customers.

- A variety of modular combinations and powerful automation modes can be selected to meet various filtering requirements.

- Many international famous brand motors, reducer, compact structure, small return clearance, high precision and bearing capacity, long service life.

- The structure is simple, easy to disassemble and easy to clean.

V-slot high-performance filter has the following advantages

- Unique filtering surface structure, with excellent scraping effect, uniform and uniform filtering aperture clearance, solid and durable, high efficiency and stability.

- It is made of 304/316 materials, with excellent pressure resistance, aging resistance, acid and alkali resistance and corrosion resistance.

- It has a smooth surface inside and outside. It has very little wear and tear on the scraper.

- High mechanical strength, can withstand greater pressure difference.

- It can improve the regeneration ability of anti - washing.

- There is no particle blockage, and can be cleaned continuously online when filtering.

Industry application

Typical application field

- Applicable fields: water treatment engineering, grease engineering, food and beverage, beer, paper water, petrochemical, biological fermentation, bio-pharmacy, ink, coating, etc.

- Applicable liquid type: amino acid, threonine, citric acid, fermented liquid, chitosan, mixed oil, edible oil, high temperature oil, palm oil, sorbitol, steroids, corn syrup, cold drinks, cheese, wax, tar, kerosene, diesel oil, coolant, paint, resin, polymer, adhesives, lubricants, rubber, methanol, ethanol, etc.